Do you imagine the same things when you hear metal pipe and metal tube? After all, both materials are often round and have a hole in the middle. But the fact is that pipes and tubes are different from each other. Choosing the right type for your application is critical. In this post, we’ll highlight what you need to know before you buy.

What is the difference between metal tubing and metal pipe? As described in this clip, a basic definition says that a pipe holds things in (like water) while a tube holds things up (like structural sections).

Let’s dig into some more formal definitions, starting with metal tubing.

Metal Tubing: What You Need to Know

Metal tubing is hollow and has precise dimensions. The wall thickness and exact outside diameter are the primary measurements here.

Metal tubes are used in an extensive range of applications, from structural engineering to automotive manufacturing. Depending on each project's application and specific tolerances, they’re also manufactured in various shapes, including round, square, triangular, and elliptical.

Most tube is rolled and welded. These products come in round, rectangular, and square shapes and are measured based on the outside diameter (OD), inside diameter (ID), or wall.

Seamless Metal Tubing

Seamless metal tubing begins life as an ingot or billet of steel. It is then pierced to form a hollow shape and formed to the required length and exact exterior diameter. The result is a steel tube without seams, eliminating structural weaknesses.

Welded Metal Tubing

Welded metal tubes begin their life as a coil steel or plate that are formed and welded longitudinally, creating a seam that runs the length of the tube.

Metal Pipe: What You Need to Know

You’ll find two types of pipes and tubes on the market: seamless and welded. Each type requires a different manufacturing process.

Metal pipe is like metal tubing in some respects but is usually defined by its nominal external diameter (as opposed to the exact external diameter for tubing). In most cases, pipes are used to contain the flow of liquid. Piping is not generally used for structural integrity.

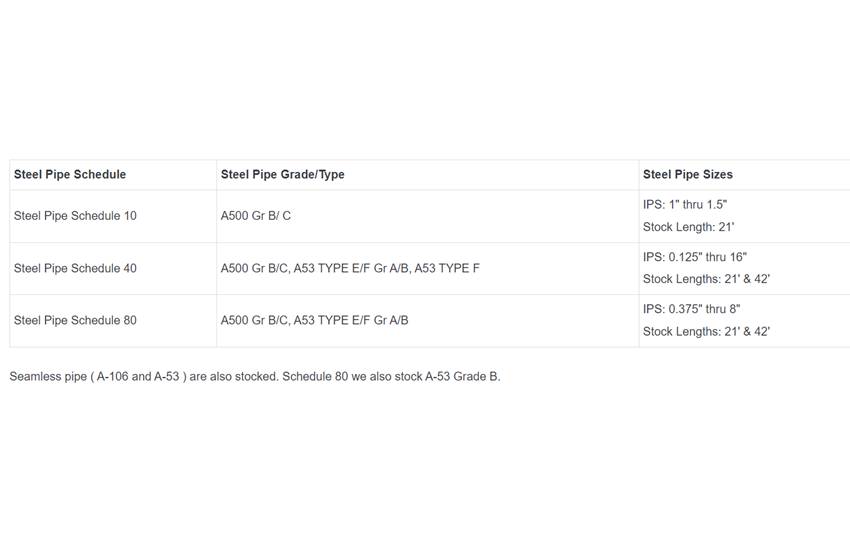

Pipe is tested for the pressure it can withstand before bursting. The term ‘schedule’ is applied to pipe, which references the wall thickness on the pipe.

A higher schedule number indicates a thicker wall. There are some instances, however, in which different-sized pipes have the same schedule number, but the actual wall thicknesses differ. Talk with your rep to learn more about the differences.

Seamless Metal Pipes

Seamless metal pipes are made in much the same way as metal tubes – an ingot or billet is pierced and shaped to create the required length, focusing on interior diameter. These types of pipes are often used in the oil and gas industry, where resistance to internal pressure is important.

Welded Metal Pipes

Welded metal pipes begin their life as a coil steel or plate that are formed and welded longitudinally, creating a seam that runs the length of the pipe.

How to Cut Metal Pipes

Cutting metal pipes, tubes ,and bars requires a thorough understanding of the desired size and tolerance. From there, you can determine which cutting method to apply. Watch the video below for more detail.

Shape and Dimensions: How They Affect Your Purchase Decision

While metal tubes and pipes can both be round, that’s not the limit of their shapes. It’s also an easy way to distinguish between the two.

Metal Tubing Shapes

Metal tubing can take many different shapes depending on the application in question. It can be round but often square, rectangular, or even triangular. Each shape has its own benefits and characteristics, including strength and resilience. Square and rectangular tubes often play roles in construction and architecture, while round tubes are often used as structural supports. Triangular tubes are used to provide rigidity and are often used in manufacturing.

Metal Pipe Shapes

Like tubes, metal pipes can be manufactured in many shapes, but the most common is round. This helps ensure efficient flow and fluid distribution. Other shapes are usually highly specialized and required only in very specific instances.

Standard Tube and Pipe Dimensions

Piping is measured by nominal outside diameter, sometimes called nominal pipe size, or NPS. This is a standard set of sizes for both high and low-pressure uses. Tubing is measured by wall thickness and exactly outside diameter. The wall thickness does not affect the outside diameter.

Choosing Your Metal Tubing and Piping

Both metal tubing and pipe play important roles in industries as wide-ranging as manufacturing and oil and gas. While the terms are often interchangeable, they are not the same product. Tubing is a more versatile product. However, steel pipe is just as critical, with fewer form factors.

When choosing metal tube and pipe, buying from a U.S.-based manufacturer that offers high-quality products to meet your needs and tolerances is important.

Ryerson: The Metal Supplier of Choice

Ryerson is a leading North American metal supplier that provides more than just metal. We respond to the ever-changing needs of manufacturing today.

With a vast inventory of steel, stainless, aluminum, alloy, and more, we are committed to providing our customers with the metal and services they need to succeed. We stock a range of shapes and sizes, or we can provide processing and fabrication for every product we sell.

Order online at Ryerson.com for comprehensive pricing and fast delivery, or contact us today to learn more about how we can meet your metal needs.

.ashx?h=300&w=940&hash=64B65E8612143E9F49094B85BB3B9AE7)