.ashx?h=300&w=940&hash=5B03FF4BFBB4B6FE043796FBC5646A2D)

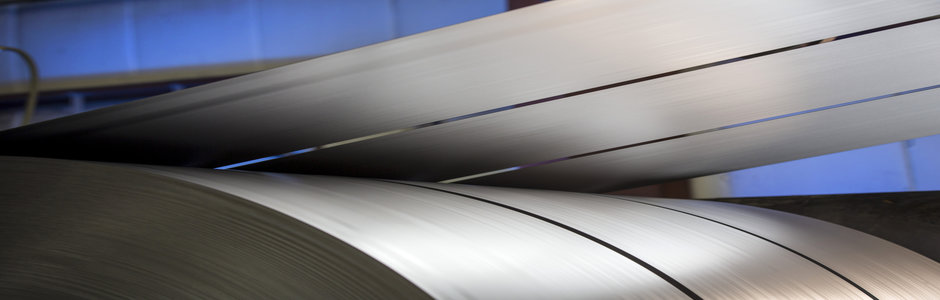

Galvanized steel has an application of zinc coating, which helps prevent against corrosion. It is one of several types of metallic coatings that can be applied to steel to help combat corrosive elements. Such protection is essential for steel used in such applications as automotive parts, appliances, construction material, and HVAC, among others.

What is the Process of Galvanizing Steel?

The galvanization process involves continuously hot dipping with a durable protective coating of zinc. This coating of zinc helps prevent corrosive substances from reaching the underlying steel.But not all steel receives the same coating rate. Each steel sheet product has its own weight designation system, as defined by the ASTM standard. For instance, A653/A653M is the common metallic-coated sheet standard for hot-dip galvanized products.

Galvanized steel is available in a variety base metal grades and coating weights. Coating designations such as G-60 and G-90 refer to the amount of coating per square foot both side total.

Let’s break it down: G-90, which is the most common coating, is equal to .9 ounces; G-60 is .6 ounces etc. The higher the coating weight, the more corrosion resistant the steel.

Does Galvanized Steel Rust?

While the protective coat of zinc does provide a barrier to corrosive substances, over time that protective coat could fade, which could expose your steel to rust.However, this only typically occurs in extreme conditions. This means it is important to understand the environmental conditions of your application. For example, those with high relative humidity or those in which the metal is exposed to constant wetting are not ideal.

Can You Weld Galvanized Steel?

Galvanized sheets can be welded and soldered. In addition, galvanized steel can be formed without flaking or peeling, and the protective qualities cannot be impaired by such actions as stamping, cold drawing, double seaming and brake or roll forming.Can You Paint Galvanized Steel?

Generally, most galvanized steel products can be painted, provided the proper pre-treatment is performed.Is Galvanized Steel Ferrous?

All steel contains iron, meaning steel is a ferrous metal. In fact, steel contains about 98% iron—it’s the rest of the makeup of the metal that truly defines what it’s best suited to do. Galvanizing steel is considered a ferrous metal.What is the Price of Galvanized Steel?

In general, galvanized steel will cost a bit more than standard steel due to the added process. The heavier the coating, the higher the cost.Galvanized vs. Galvanneal

Galvanneal coatings contain 9-12% bulk iron, along with aluminum. These sheets are heat treated after coating to produce zinc-iron alloy and eliminate the spangle.Galvannealed sheets can be painted without further surface preparation aside from normal cleaning and may be subject to bending and simple forming without impairing their paintability or corrosion resistance. Typical coating weights are A60 or A40.

Typical applications of galvanneal include sign boards, metal doors and partitions, truck and trailer bodies, and heater and furnace parts, among others.

Is Galvanized Steel RoHS Compliant?

RoHS (Removal of Hazardous Substances) is a directive standard from the European Union aimed at preventing risks posed to human health and the environment related to the management of electronic and electrical waste.RoHS applies to metals in relation to hazardous substances used with surface treatments applied to coated sheets, including galvanized steel. These hazardous substances include mercury. lead, cadmium, PBBs, PBDEs, as well as hexavalent chrome, common as a chemical treatment option on galvanized products.

Ryerson stocks RoHS-compliant coated products.

Ready to select the right piece of galvanized steel for your next project? Click here to browse our selection of material.

.ashx?h=300&w=940&hash=357B3E0577C9475EB1306A911B929DAF)