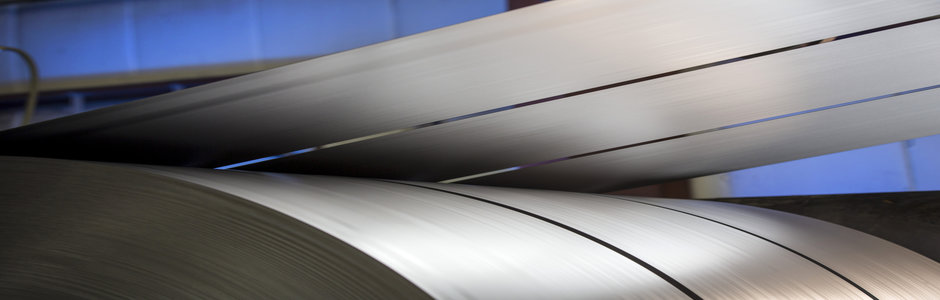

Is there a better way to manage your steel inventory? From maintaining optimal stock levels to navigating pricing and delivery challenges, your time could be better spent working on the things that make you money.

It may be an opportunity to assess the suitability of implementing a vendor-managed inventory (VMI) program for your steel supply needs. This strategy is particularly beneficial for manufacturers procuring substantial quantities of materials regularly.

Consider the merits of such a program through a four-point plan, presenting a compelling case for collaboration with steel suppliers such as Ryerson.

Point One: Cost Savings

By outsourcing the responsibility of inventory management to the steel supplier, manufacturers can reduce costs associated with warehousing, labor, and carrying excess inventory. This leads to improved cost efficiency and better allocation of resources.

Ben Bell is a general manager with a unit within Ryerson called RCSS (Ryerson Carbon Sheet Solutions). RCSS works with larger manufacturers that purchase carbon flat roll in large quantities, helping to ensure they get the right price and are using the most optimal supply chain.

Bell says often it comes down to the financial implications for manufacturers, especially regarding free cash flow. By holding inventory on its floor, Ryerson acts as an intermediary, providing a financial advantage to manufacturers and reducing the immediate financial burden.

Point Two: Reducing Lead Times

With the supplier managing the inventory on-site, lead times are often minimized. This allows manufacturers to respond quickly to changes in demand, market conditions, or unforeseen disruptions, contributing to increased agility in the supply chain.

A VMI program ensures a consistent and reliable steel supply, reducing the risk of production delays due to stockouts. This can lead to improved production planning and overall operational efficiency.

Point Three: Risk Mitigation

The steel supplier can provide insight into monitoring market trends, ensuring that the manufacturer is less exposed to price fluctuations and market uncertainties.

Ryerson’s in-house risk management team can provide an asset to your steel-purchasing strategy. By offering pricing solutions such as hedging, commodities such as steel, aluminum, copper, and stainless steel, manufacturers can potentially mitigate the impact of market volatility on their costs.

“Hedging becomes particularly relevant when overall costs are a concern,” says Nick Webb, Ryerson’s director of risk management and commodities hedging. “Whether it's the cost of borrowing or the cost of raw metal, hedging can help companies manage and mitigate these cost pressures.”

Webb does caution, however, that a hedging strategy is best applied when confident in your material needs.

“Hedging is often considered when customers have a decent backlog or are confident about their material needs,” adds Webb. “This allows Ryerson to work with them to hedge a portion of their requirements, providing some level of risk management while supporting customer confidence.”

Point Four: Customized Inventory

A reputable steel supplier with a VMI program can tailor the inventory management system to meet the manufacturer's specific needs. This can include adjusting order quantities, delivery schedules, and inventory levels based on production requirements.

A big portion of this point comes with gaining data visibility and being able to see where you stand with cost and inventory at any given time.

Ryerson works with manufacturers to develop advanced tracking and reporting tools customized to their operations. Bell provides customers a report showing the variance between their forecasted and actual sales. This assessment helps identify areas for improvement and potential risks in the supply chain.

“With real-time visibility into inventory levels, usage patterns, and other relevant data, it helps our customers make truly informed decisions about their supply chain,” adds Bell.

A vendor-managed inventory program is part of a customized metal solution from Ryerson.

.ashx?h=366&w=650&hash=BF396CE37EB5A2ACD500065484591A03)

Ryerson is a leading North American metal supplier that provides more than just metal. We respond to the ever-changing needs of manufacturing today.

With a vast inventory of steel, stainless, aluminum, alloy, and more, we are committed to providing our customers with the metal and services they need to succeed. We stock a range of shapes and sizes, or we can provide processing and fabrication for every product we sell

Order online at Ryerson.com for comprehensive pricing and fast delivery, or contact us today to learn more about how we can meet your metal needs

.ashx?h=554&w=750&hash=D1C2D9CF0F5D19939BED67801B5A3672)

.ashx?h=300&w=940&hash=64B65E8612143E9F49094B85BB3B9AE7)