In the digital age, data is king, and data centers are the kingdoms. Therefore, it is no surprise that in an increasingly interconnected world, data centers are experiencing an unprecedented surge in demand. As technology evolves and our reliance on data deepens, the need for robust, scalable data centers has never been more critical.

As of 2024, the global data center market is comprised of 8,000 data center locations worldwide, according to research firm Astute Analytica. The firm further states that worldwide data center capital expenditure (capex) grew by 4% in 2023, reaching $260 billion, and is expected to hit $792.29 billion by 2032.

Chelsea Hunt, Ryerson's vertical market manager for climate solutions, characterizes the current market as being "at a point where hyperscale data centers are set to double their capacity every four years." This exponential growth is fueled by the rise of generative AI and the relentless digitization of countless aspects of our lives.

Major players like Amazon, Google, and Microsoft are investing billions in expanding their data center infrastructure, triggering a ripple effect across the entire industry.

Naturally there is crucial link between metal production and data center construction. So much so that we are seeing announcements like Nucor's recent investment in a data center infrastructure company. In all, this underscores the pivotal role of metal in this burgeoning market.

Ryerson Serves Metal Needs of Data Centers

With this surge in data center construction comes a surge in demand for the raw materials needed to build them. Metal, in all its forms, lies at the heart of this demand. From enclosure racks to cable management systems, from liquid cooling pipes to HVAC systems, the data center ecosystem is inherently metal-intensive.

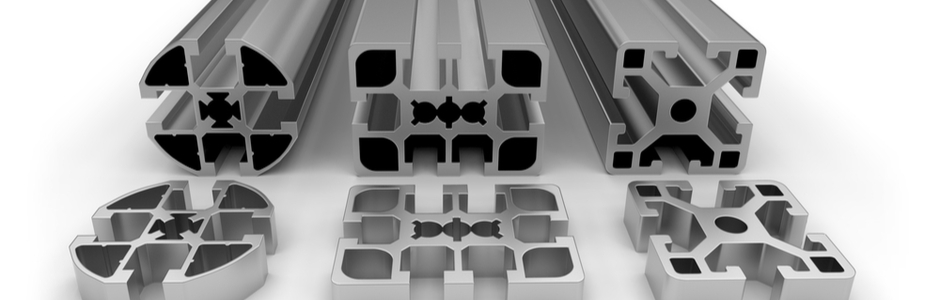

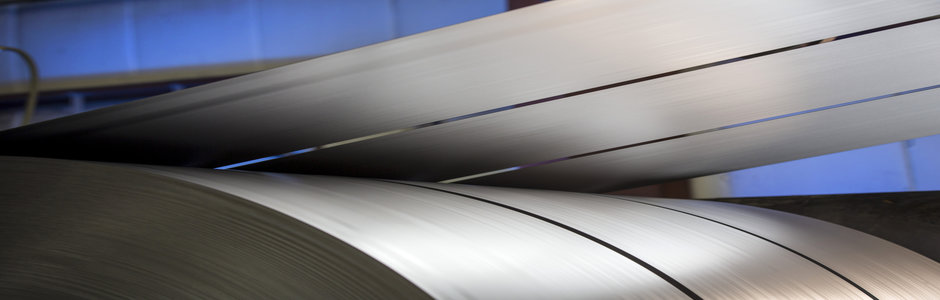

Metal is a main component to these data centers. For example, flat roll steel shapes the enclosures, aluminum extrusions are critical to containment aisles, aluminum flat roll is used for cable racking, and stainless steel pipe is used in cooling applications, among others.

For those looking to build out their supply chain in this market for the first time, or address some current bottlenecks, Ryerson can provide a range of services beyond simply supplying the material. Two of these areas, according to Hunt, are supply chain management and fabrication capabilities.

Ryerson's fabrication capabilities offer a competitive edge in a market where customization is often a must. Whether tube laser cutting for precise components or flat laser and bending for custom enclosures, Ryerson has the expertise and expansive network to meet the unique needs of data center builders.

For Ryerson, it's about more than just a set of capabilities. It's about developing a comprehensive approach to managing the manufacturing and quality process and delivering high-quality parts on time, every time.

“We’re able to find the best solution—not just the nearest, but the one that creates the greatest ongoing value for the manufacturer. That really sets us apart when customers expand their capacity,” says Mike Nauman, general manager with Ryerson’s advanced processing division.

Flex Your Manufacturing Capacity

Stocking programs like Vendor Managed Inventory (VMI) further streamline the supply chain, ensuring that essential materials are always on hand when needed.

By outsourcing the responsibility of inventory management to a steel supplier like Ryerson, companies can reduce costs associated with warehousing, labor, and carrying excess inventory. This can lead to improved cost efficiency and better allocation of resources.

But Ryerson's role extends beyond mere supply and fabrication. With a roster of data center clients already in its portfolio, Ryerson understands the specific challenges and bottlenecks facing the industry.

Ben Bell is a general manager with a unit within Ryerson called RCSS (Ryerson Carbon Sheet Solutions). RCSS works with larger manufacturers that purchase carbon flat roll in large quantities, helping to ensure they get the right price and are using the most optimal supply chain.

“With real-time visibility into inventory levels, usage patterns, and other relevant data, it helps our customers make truly informed decisions about their supply chain,” adds Bell.

A Budding Infrastructure

As the data center market continues to expand at breakneck speed, those looking to build out the infrastructure need support in many ways.

“With years of experience serving the enclosure market, Ryerson is well-equipped to navigate the fluctuations in demand that accompany the data center boom,” adds Hunt. “By partnering with a reliable service center like Ryerson, companies can ensure quick turnarounds on materials, essential for meeting the rapid pace of construction.”

Do you have metals needs for your data center project? Contact Chelsea Hunt, Ryerson's Vertical Market Manager, at chelsea.hunt@ryerson.com

.ashx?h=300&w=940&hash=64B65E8612143E9F49094B85BB3B9AE7)